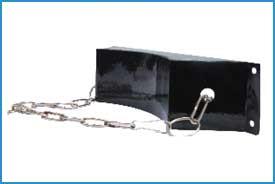

Gas Control Box

Gas Control Box is used when there is more than one Gas Chromatogragh. It helps to control the flow and pressure of different gases for different GC’s. From a Gas Purification System, purified gases can be supplied to a number of Gas Chromatographs through Gas Control Boxes when each instrument requires different delivery pressure & flow. Gas Control Box is generally installed between Gas Purification system and Gas Chromatograph. It consist of pressure gauge, pressure regulator and toggle valves. This also isolates system.